COMMITMENT TO QUALITY

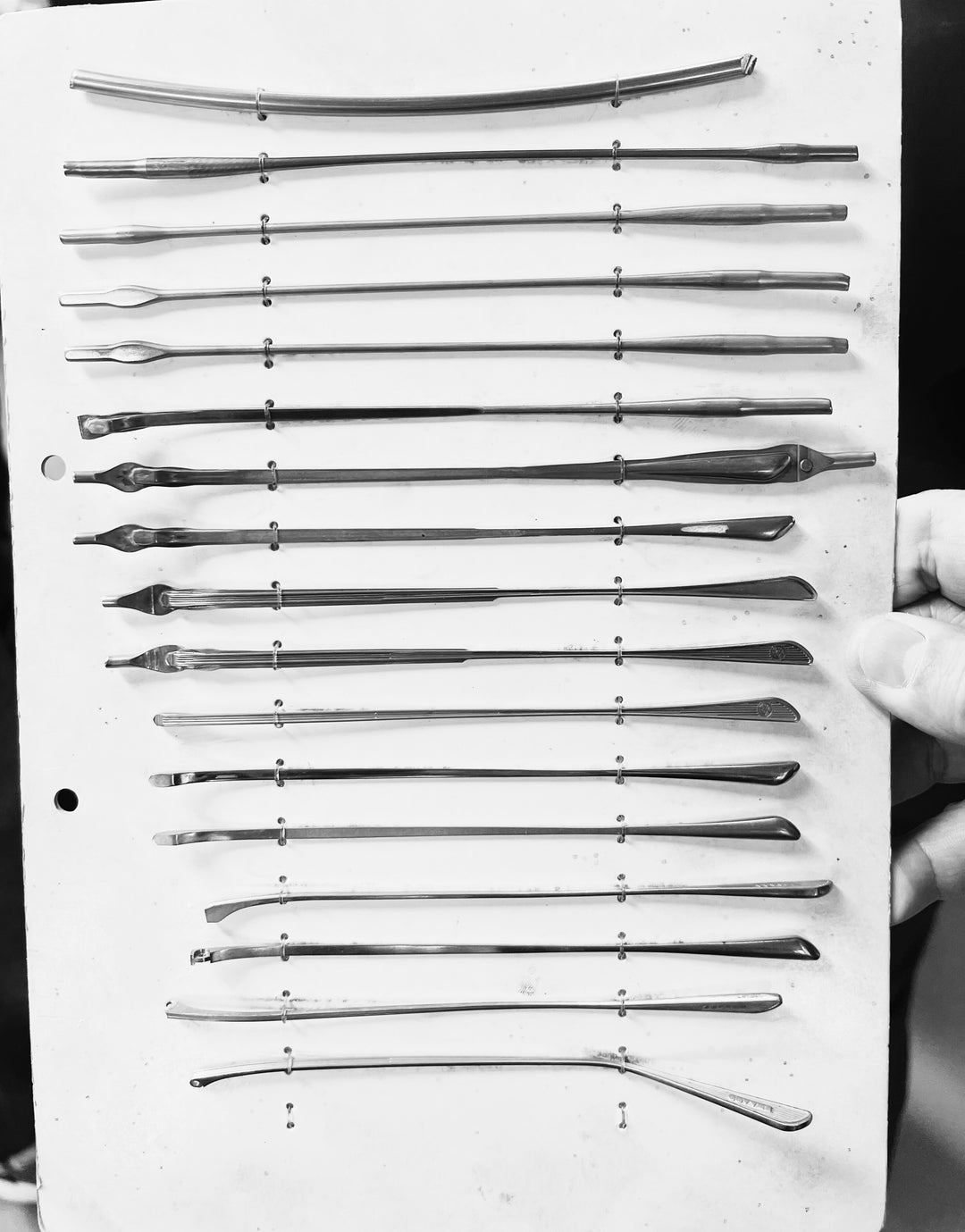

Sabae’s master artisans meet aerospace-grade precision.

At Esmont, eyepiece isn’t just shaped—it’s engineered. Inspired by aviation design, every eyepiece endures 300 meticulous steps, ensuring durability.

Like aviation’s black boxes, our Kaizen refinement process eliminates imperfections at every stage. The result? Eyewear built to withstand time, not just trends.